Foil stamping is a specialty printing process that uses metal dies, heat, and pressure to apply foil films. This process creates a visually appealing and high-quality finish, adding a touch of luxury and sophistication to various products. CrownPackages understands the power of impactful packaging, and that’s why we offer a variety of finishing techniques, including foil stamping. This comprehensive guide delves into the world of foil stamping, empowering you to create packaging that resonates with your target audience.

Applications of Foil Stamping

Foil stamping boasts a wide range of applications, making it a versatile tool for brands across industries. Here are just a few examples:

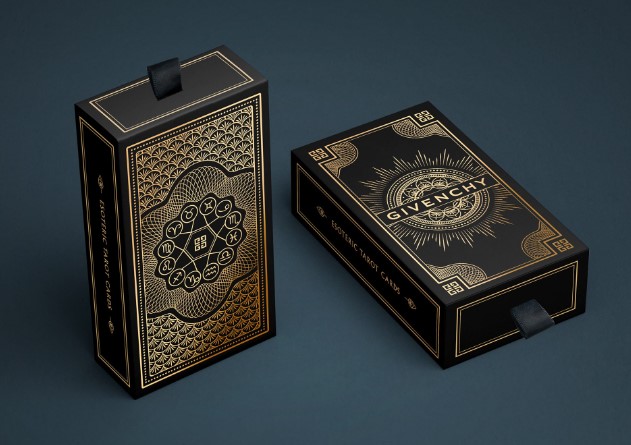

- Luxury Packaging: Foil stamping adds a touch of sophistication and elegance to packaging for high-end products, from cosmetics to chocolates.

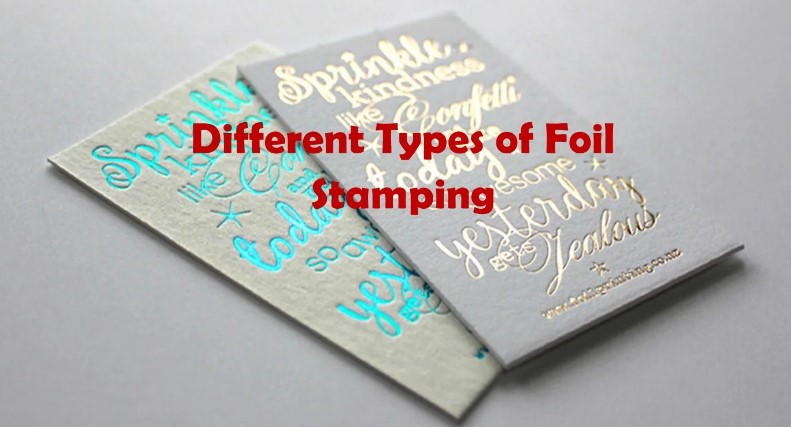

- Stationery: Elevate your business cards, letterheads, and invitations with the brilliance of foil stamping.

- Product Labels: Make your products stand out on store shelves with eye-catching foil-stamped labels.

- Marketing Materials: Brochures, flyers, and presentation folders gain a touch of luxury with foil-stamped accents.

- Certificates and Awards: Foil stamping adds a prestigious feel to certificates and awards, making them truly memorable.

Foil hot stamping can be seen on diverse products, from wine packaging with gold foil accents to luxury chocolate boxes adorned with intricate foil designs.

Types of Foil Stamping

Choosing the right type of foil hot stamping depends on the substrate and the desired finish. Here are the four primary hot stamping techniques:

Flat Foil Stamping

- Uses a copper or magnesium metal stamp to transfer the foil onto the substrate.

- Produces a raised foil design.

- Simple and economical process.

Vertical Foil Stamping

- Suitable for stamping foil designs on flat substrates and cylindrical shapes.

- Commonly used for items like tubes and bottles.

Sculpted Foil Stamping

- Utilizes brass dies to create a raised image with a clearly defined and carved look.

- Ideal for detailed and intricate designs.

Peripheral Foil Stamping

- Applies foil heat transfers to the outer perimeter or circumference of the product.

- Used for round or cylindrical items.

Types of Foils Used

Different types of foils can create distinctive packaging that aligns with your marketing campaign or brand image. CrownPackages offers a variety of foils, including:

- Metallic Foil: Provides an attractive patina in colors like silver, gold, blue, copper, red, and green.

- Matte Pigment Foil: Features a muted appearance with intense color depth.

- Gloss Pigment Foil: Combines high gloss with a non-metallic finish, available in various colors.

- Holographic Foil: Transfers hologram images for a futuristic, eye-catching look.

- Special Effects Foil: Creates a range of textures, mimicking leather, pearl, or marble appearances.

Process of Foil Stamping

Foil hot stamping is a precise process that involves several key steps:

- Die Creation: A metal die, typically made of brass, magnesium, or copper, is etched with your desired design.

- Substrate Selection: Foil stamping works best on smooth, even surfaces. CrownPackages offers a wide variety of paper stocks and other materials suitable for foil hot stamping.

- Foil Selection: Our team will help you select the perfect foil based on your desired color, finish, and effect.

- The Stamping Process: The heated die is pressed onto the substrate, applying pressure and heat to activate the foil’s adhesive and bond it to the material.

Quality Control: Our meticulous quality control procedures ensure a flawless finish on every foil-stamped piece.

The Hot Stamping Process

Hot stamping is a machine-based process where a foiling die, etched with your design, is heated and stamped with high pressure to bond a thin layer of foil to the substrate. The core approach of applying heat and pressure delivers the desired result on the material. Dies can be made of brass, magnesium, or copper. Although purchasing the die is expensive, it offers multiple uses and is worth the investment for consistent high-quality results.

The Benefits of Foil Stamping

Foil hot stamping offers several benefits:

- Since this stamping doesn’t use ink, the foil color remains consistent regardless of the substrate color.

- Light and metallic foils can be used on darker colored papers, expanding design possibilities.

- Hot stamping allows for various finishes, enabling you to experiment with your branding and packaging.

- The striking effect of foil stamping helps your products stand out from competitors, adding perceived value to your brand.

Elevate Your Packaging with CrownPackages

Foil stamping has the potential to elevate and breathe new life into existing packaging designs. Whether you want to add a touch of elegance to your logo or enhance your artwork, foil stamping provides a higher perceived value for your products.

Partnering with a product specialist from CrownPackages allows you to optimize every aspect of your packaging, from structure to artwork, ensuring that your packaging not only looks stunning but also meets all your functional requirements.

For more information on other print finishing options, explore our offerings on Embossing & Debossing, Spot UV, Window Patching, and Soft Touch. Contact CrownPackages today to discuss how foil stamping can enhance your product packaging.

Conclusion

Ready to transform your packaging with the brilliance of foil stamping? Contact CrownPackages today! Our team of experts will help you explore the possibilities of foil stamping and create packaging that makes a lasting impression on your target audience.