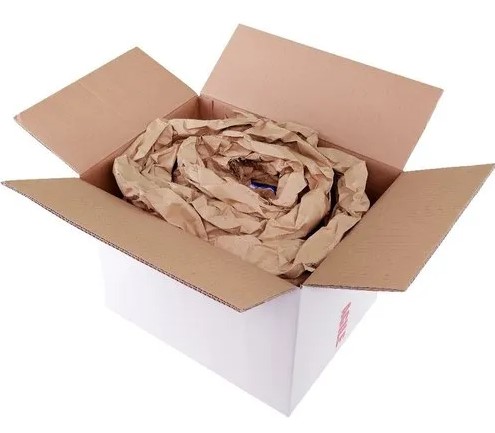

A product’s journey extends far beyond the click of a “buy” button, when shipping products, what’s inside the box matters just as much as the packaging itself. The unboxing experience can be a powerful branding tool, shaping customer perception and fostering loyalty. At CrownPackages, we understand the importance of presentation, and void fillers in packaging play a crucial role in creating a memorable and positive unboxing experience.

What is a Void Filler?

Void fill, also known as package stuffing or shipping padding, plays a critical role in protecting products during transit. It is vitallly important in preventing product shifting, rough handling, and potential damage due to drops. They fill empty spaces within the box, preventing items from shifting and absorbing impact during transportation.

Benefits of Void Fillers in Packaging

Void-filled boxes offer more than just protection; they enhance brand appeal and create a memorable unboxing experience for customers. These effective void fillers can add value to your packaging strategy.

- Enhanced Protection: Void fillers provide a crucial layer of cushioning, safeguarding your products from damage caused by bumps, drops, and vibrations during shipping. This minimizes the risk of returns and ensures your customers receive their purchases in pristine condition.

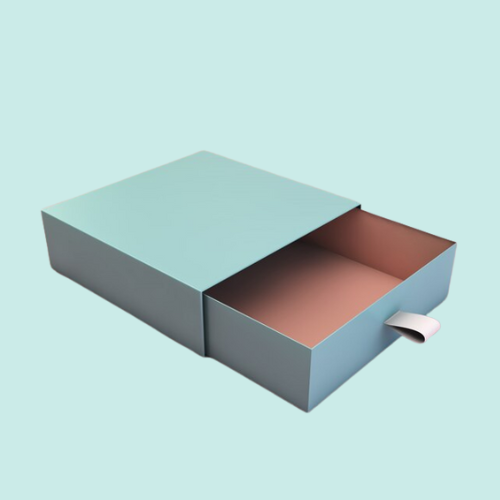

- Optimized Packaging: The right void filler helps you choose the perfect box size for your product. By filling empty spaces, you can opt for a snugger fit, minimizing wasted space and potentially reducing shipping costs.

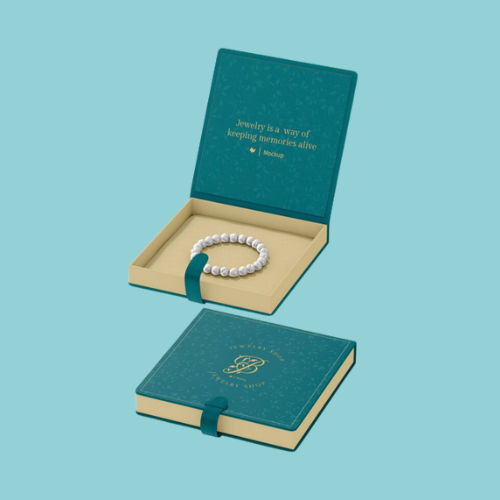

- Aesthetics and Branding: Void fillers can go beyond basic functionality. CrownPackages offers a variety of visually appealing and sustainable options that can elevate your brand image and create a memorable unboxing experience.

Choosing the Right Filler for Your Packaging

With a diverse range of void filler options available, choosing the right one can seem overwhelming. CrownPackages is here to simplify the process. Here are some key factors to consider:

- Product Protection Requirements: Evaluate the fragility of your product. Delicate items require substantial cushioning, while sturdier items may benefit from void fillers that focus on preventing movement.

- Sustainability: CrownPackages prioritizes eco-friendly solutions. We offer a wide range of biodegradable and recyclable void fillers, allowing you to minimize your environmental impact.

- Branding and Presentation: Consider how void fillers can contribute to your brand identity. Customizable options like printed tissue paper can add a touch of luxury and reinforce your brand message.

Popular Packaging Filler Material Types

Explore various void filler options, from cost-effective paper fillers to environmentally friendly alternatives like wood excelsior and biodegradable bio foam. CrownPackages offers a variety of high-quality void fillers to cater to your specific needs:

- Paper Fillers: An eco-friendly and cost-effective choice, paper void fillers come in various forms, including packing paper, crinkle paper, and honeycomb paper. These options provide cushioning and can be customized with your brand logo for a touch of personality.

- Cardboard Fillers: Cardboard partitions and dividers are ideal for stabilizing multiple items within a box, preventing them from colliding during transport. Customizable cardboard inserts can further enhance presentation and showcase your product effectively.

- Bio-Based Fillers: These eco-friendly alternatives to traditional packing peanuts are derived from plant-based materials, offering comparable protection with a lower environmental footprint.

- Packaging Air Pillows: These lightweight, inflatable cushions are a space-saving solution for void filling. While not as visually appealing as other options, they offer effective protection for non-fragile items.

- Wood Excelsior: Delve into the unique sensory experience offered by wood excelsior and its suitability for rustic and luxury products.

- Bubble Wrap: Explore the quick and budget-friendly protection offered by bubble wrap and its considerations regarding customization and environmental impact.

CrownPackages Your Partner in Packaging Excellence

At CrownPackages, we go beyond providing void fillers. We offer expert guidance to help you select the perfect solution for your products, ensuring optimal protection, efficient packaging, and a brand-enhancing unboxing experience.

Contact CrownPackages today and let’s discuss your void filler needs. Together, we can create a packaging solution that protects your products, reflects your brand values, and delights your customers!

Conclusion

At CrownPackages, we recognize the significance of packaging, where void fillers play a vital role. Not only do they protect products during transit, but they also enhance brand appeal and create memorable experiences for customers. With a wide range of eco-friendly options and expert guidance, CrownPackages is your partner in packaging excellence. Contact us today to elevate your packaging strategy and delight your customers every step of the way!

Frequently Asked Questions

What is filler material in packaging?

Filler materials in packaging refer to substances used to occupy empty spaces within boxes or containers, ensuring products remain stable during transit. CrownPackages offers various types, including paper, foam, plastic bubbles, and molded fiber, each serving specific functions in packaging.

What is dunnage also known as void fillers?

Dunnage, also known as void fillers, are materials like dunnage bags that fill empty spaces between cargo and container walls, preventing movement during transit. CrownPackages provides dunnage solutions that create a cushioning barrier, absorbing shocks and vibrations to protect items during transportation.

What is void fill packaging?

Void fill packaging, such as bubble wraps or eco-friendly corrugated wraps, protects fragile items by filling empty spaces in packaging. CrownPackages offers void fill solutions like recyclable honeycomb padded paper, providing cushioning to absorb impacts during transit while enhancing sustainability.

How to fill void box?

Filling void spaces in boxes is crucial to prevent product movement during transit. CrownPackages offers packing peanuts, small foam shapes that effectively fill empty spaces, preventing movement and protecting items from damage during shipping.

What is cardboard filler?

Cardboard filler, inspired by the alveolar structure of beehives, is a layered packaging system that safeguards objects during transportation by filling empty spaces to cushion against impacts. CrownPackages provides innovative and recyclable cardboard filler solutions for enhanced product protection.

What is void fill made of?

Void fill materials like foam packing peanuts are designed to protect fragile objects during shipping. CrownPackages’ foam peanuts are made of polystyrene, interlocking when compressed to prevent movement and absorb impacts, ensuring products reach their destination intact.

What are the benefits of void fill?

Void fillers prevent product movement during transit, providing cushioning to absorb impacts, bumps, and vibrations. CrownPackages’ void fill solutions enhance the unboxing experience for customers while ensuring products are delivered safely and securely.

Is void fill recyclable?

CrownPackages offers recyclable void fill options like honeycomb padded paper, responsibly sourced from renewable kraft paper. Our eco-friendly design effectively cushions and protects fragile items during transit while promoting sustainability and cost-saving measures.

What is a paper filler?

Paper fillers are mineral-based powder products that fill spaces between cellulose fibers during paper manufacturing. CrownPackages’ paper fillers contribute to paper’s structural integrity and quality, ensuring optimal performance in packaging applications.

Which filler is used in the paper industry?

Ground calcium carbonate (GCC), kaolin, and precipitated calcium carbonate (PCC) are common fillers used in papermaking. CrownPackages offers quality fillers for the paper industry, including GCC, kaolin, and other mineral-based options, ensuring high-quality paper production.