Accurate measurements are paramount in the packaging, especially when it comes to crafting custom solutions for your brand. Whether for shipping, storage, or product presentation, understanding how to correctly measure box dimensions is crucial for ensuring optimal fit, minimizing costs, and safeguarding products during transit. In this extensive guide, we’ll delve into the intricacies of box dimension measurement, covering everything from the basics of length, width, and depth to calculating volume and addressing the importance of internal/external dimensions.

Importance of Box Dimensions

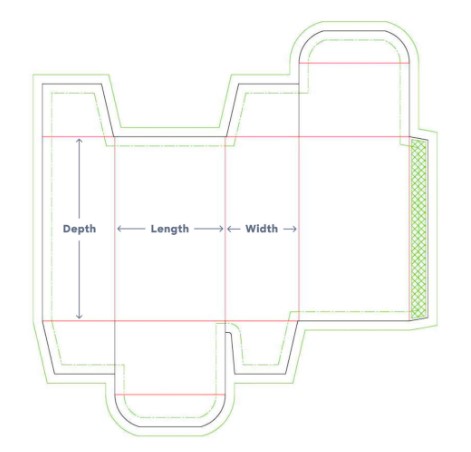

Box dimensions are typically expressed as length, width, and height (or depth). However, confusion can arise due to the possibility of measuring internal or external dimensions. Here’s how to avoid this pitfall:

- Industry Standard: The industry standard for box dimensions relies on internal measurements, not external ones. This ensures the perfect fit for your product within the packaging.

- Internal vs. External Measurements: External measurements include the box’s thickness, which can lead to ill-fitting packaging if used for calculations. Internal measurements provide a more accurate representation of the usable space within the box.

Remember: When working with CrownPackages for custom packaging solutions, always provide internal box dimensions.

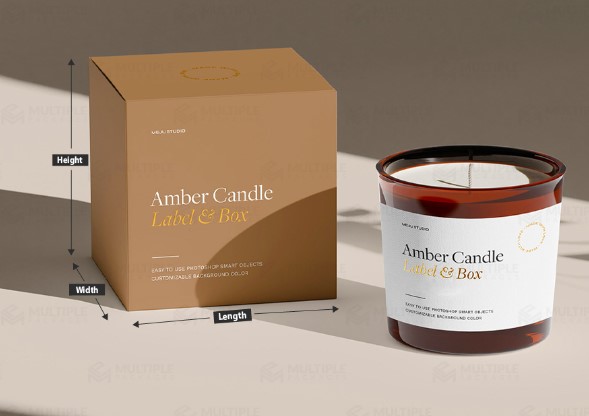

The Three Dimensions of a Box

Before diving into the nitty-gritty of box measurement, it’s essential to grasp the fundamental dimensions of a box: length, width, and depth. These dimensions, when accurately recorded, provide the foundation for designing tailored packaging solutions. CrownPackages emphasizes precision in measuring these dimensions, as even slight inaccuracies can have significant implications for product safety and cost-effectiveness.

- Length: Refers to the longest side of the box when viewed from the top.

- Width: Denotes the shorter side of the box when observed from the top.

- Depth (Height): Represents the side perpendicular to both the length and width.

Understanding these dimensions and their respective positions within the box is crucial for obtaining precise measurements.

Calculating the Volume of a Box

Once the length, width, and depth of a box are determined, the next step is calculating its volume. Volume measurement plays a pivotal role in optimizing material usage, estimating shipping costs, and ensuring adequate space for products. CrownPackages utilizes a straightforward formula to calculate box volume:

Volume=Length×Width×Depth

This formula provides a cubic measurement, enabling CrownPackages to assess packaging requirements accurately. While knowing which measurement corresponds to each dimension is technically optional, maintaining this information fosters clarity and consistency in packaging design.

The Issue of External Dimensions

An often-overlooked aspect of box measurement is the distinction between internal and external dimensions. CrownPackages emphasizes the importance of measuring internal dimensions, as these dimensions directly impact the fit and security of products within the packaging. While external dimensions may seem more intuitive to measure, they fail to account for the thickness of the box material, potentially leading to ill-fitting packaging.

Corrugated boxes, a staple in CrownPackages’ offerings, exemplify the significance of measuring internal dimensions accurately. The fluted texture inherent in corrugated material adds thickness, necessitating precise internal measurements to ensure a snug fit for products.

How to Accurately Measure Box Dimensions: Step-by-Step Walkthrough

To facilitate accurate box dimension measurement, CrownPackages provides a comprehensive step-by-step guide:

Tools You’ll Need

- Ruler (for small boxes)

- Tape measure (ideal for most boxes)

- Yardstick (useful for larger boxes)

Step 1: Measure the Length

Identify the longest side of the box and use a ruler, tape measure, or yardstick to measure from the leftmost to the rightmost edge, ensuring alignment for precise measurement.

Step 2: Measure the Width

Measure the side adjacent to the length, ensuring a straight, horizontal alignment across the box’s width.

Step 3: Measure the Height (Depth)

Measure from the top down to the base, ensuring perpendicular alignment to the box’s base to avoid slanting.

Tips for Accurate Measurements

- Consistency is Key: Use the same unit of measurement (inches, centimeters, etc.) throughout for all dimensions. This is crucial for shipping calculations and ensuring a proper fit.

- Double-Check for Accuracy: Especially with larger or irregularly shaped boxes, take measurements twice to confirm their accuracy.

- Accounting for Irregularities: If the box isn’t perfectly rectangular or square, measure at its widest and tallest points to account for any bulges or variations.

CrownPackages underscores the importance of consistency, accuracy, and accounting for irregular shapes during the measurement process. By adhering to these guidelines, customers can obtain precise dimensions for their packaging needs, ensuring seamless packing, shipping, and storage processes.

Conclusion

In conclusion, accurate box dimension measurement is a cornerstone of CrownPackages’ commitment to delivering tailored packaging solutions. By understanding the intricacies of box dimensions and adhering to precise measurement techniques, CrownPackages ensures that every package is crafted with meticulous attention to detail, safeguarding products and enhancing customer satisfaction.

Frequently Asked Questions

How do you measure box and packaging dimensions?

Measure the length, width, and height. Length is the longest side, width is the shortest, and height is perpendicular to length and width.

How do I know my package dimensions?

Determine package measurements in inches by starting at the longest point, rounding each measurement to the nearest whole number, then multiplying length by width by height.

How do I find the right size box?

Measure the product’s length, width, and depth, adding 1/8 to 1/4 inch to each dimension for wiggle room.

What are normal package box dimensions?

Common sizes include 17” x 12 ⅜” x 12 ⅜”, 18” x 16” x 18”, and 18” x 18” x 24”, suitable for various items like books, towels, and kitchen appliances.

How to measure a box depth?

Length is the longest side, width is the shortest, and depth is measured from the base to the top.

Which comes first in dimensions?

The industry standard is width first, then height, and finally depth.

What is the most common packing box size?

Medium boxes (18 x 18 x 15 inches) are versatile for moving office supplies, toys, appliances, and household items.

What is the difference between size and product dimension?

Product dimensions refer to a product’s height, width, and depth, aiding shoppers in purchase decisions. Size generally refers to overall dimensions.