Corrugated cardboard stands as a testament to innovation and durability, with a rich history spanning over two centuries. CrownPackages embarks on a journey to explore the origins and evolution of this remarkable packaging material, highlighting its enduring relevance in modern times.

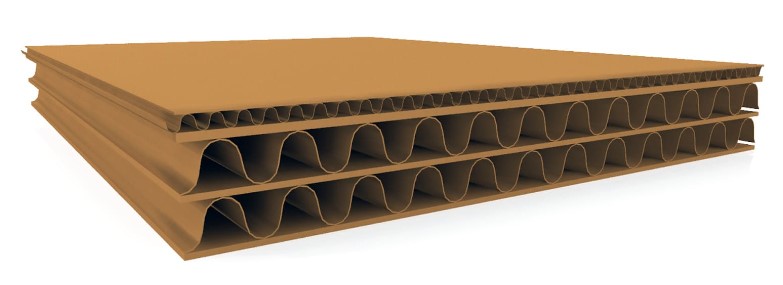

The Anatomy of Corrugated Cardboard

At its core, corrugated cardboard features a distinctive composition characterized by a fluted layer securely bonded between two robust cardboard sheets. CrownPackages sheds light on the structural dynamics of corrugated cardboard, emphasizing its versatility in enhancing structural strength through varying fluted layer configurations. This fundamental arrangement serves as the cornerstone for corrugated cardboard sheets and the resulting packaging boxes.

A Paradigm Shift in Shipping

The inception of corrugated cardboard as a shipping solution traces back to the pioneering efforts of Malcolm McLean in 1871. CrownPackages delves into the groundbreaking idea conceived by McLean, which revolutionized global transportation processes by introducing corrugated cardboard boxes designed for efficient loading and unloading onto ships. This innovative concept not only expedited shipping operations but also set the stage for further advancements in packaging technology.

Propelling Corrugated Packaging Forward

Over the years, manufacturers have continued to refine corrugated cardboard production techniques, leveraging extensive research and customer feedback to enhance product performance. CrownPackages explores the evolution of proprietary lining and fluting, emphasizing the importance of internal innovation in ensuring the strength and durability required for securely packing and transporting valuable items.

Types of Corrugated Stock: Tailoring Solutions to Unique Needs

Corrugated stock encompasses a versatile array of materials tailored to meet diverse packaging requirements. CrownPackages offers insights into the various types of corrugated stock, ranging from Normal Slotted Glued Containers (RSC) to specialized configurations such as die-cut containers and multi-walled designs. Each type is carefully crafted to deliver optimal strength, durability, and protection for packaged goods.

Manufacturing Process of Corrugated Packaging

CrownPackages embarks on a journey to unravel the intricate process behind the creation of corrugated packaging, shedding light on its sustainable origins and remarkable recycling capabilities. By delving into the manufacturing process, we gain insights into the fundamental components that form the backbone of corrugated stock.

Sourcing and Recycling

Derived primarily from trees, corrugated packaging emerges as a sustainable solution, with a robust recycling infrastructure ensuring its continued eco-friendly footprint. CrownPackages emphasizes the industry’s commitment to sustainability, with a recovery rate reaching approximately 90% over the past eight years. Through meticulous collection, sorting, and compression, old corrugated containers (OCC) are transformed into compact bales, ready for the next phase of production.

Pulping and Formation

At the heart of the manufacturing process lies the pulping stage, where recycled corrugated material undergoes a transformative journey. CrownPackages illustrates the pulping process, likening it to a large blender, where fiber and water combine to form a slushy pulp. Through meticulous agitation and extraction of impurities, a continuous fiber mat is created, paving the way for the next stage of compression and moisture elimination.

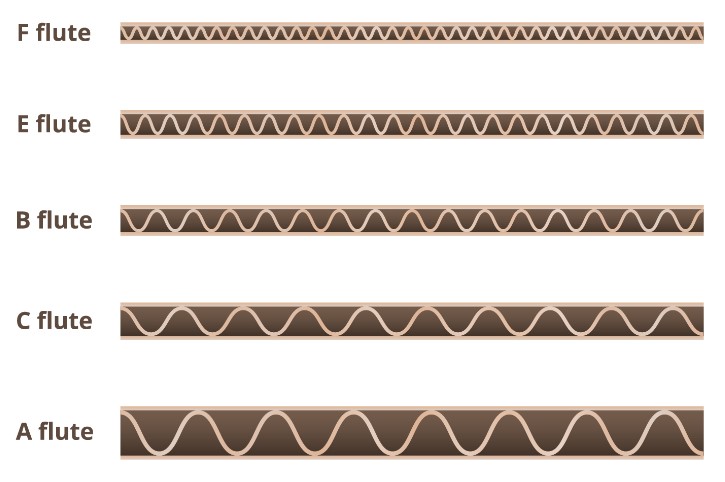

Understanding Corrugated Flute Types

Corrugated packaging boasts a variety of flute types, each offering unique characteristics and applications. CrownPackages delves into the intricacies of A, B, and E flutes, shedding light on their respective strengths and suitability for different packaging needs.

A-Flute

A-flute, with its generous 5mm thickness, emerges as the optimal choice for items requiring superior cushioning and stacking robustness. CrownPackages highlights the exceptional cushioning properties of A-flute, making it ideal for safeguarding delicate products during transit.

E-Flute

E-flute distinguishes itself with its remarkably thin profile, measuring between 1mm to 1.5mm in thickness. CrownPackages emphasizes the outstanding strength of E-flute against squeezing and crushing, making it a preferred option for applications requiring both durability and space efficiency. Additionally, its smooth surface lends itself well to high-quality printing, enhancing brand visibility and aesthetics.

B-Flute

B-flute, with its thickness of around 3.2mm or ⅛ inch, strikes a balance between durability and space optimization. CrownPackages highlights the resilience of B-flute, capable of withstanding pressure without succumbing to crushing or puncturing. With approximately 49 waves per foot of packaging, B-flute proves invaluable for interior packaging where toughness is paramount.

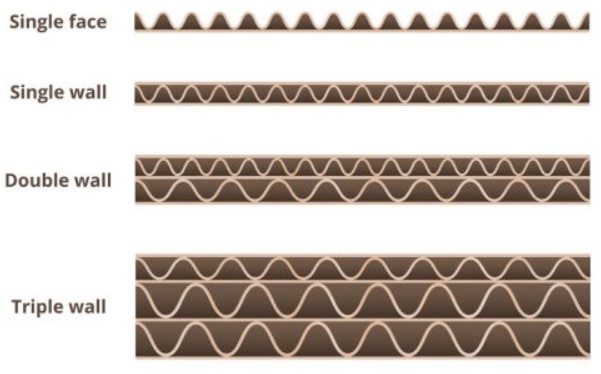

Types of Corrugated Boards

The discussion extends to the various types of boards utilized in corrugated box construction, ranging from single-wall to triple-wall configurations. CrownPackages elucidates the distinct characteristics of each board type, from the versatile single-wall boards commonly found in shipping boxes to the sturdy triple-wall boards reserved for commercial components and produce bins. By aligning board selection with packaging needs, businesses can ensure optimal protection and transportation of their products.

Single-Wall Boards

Single-wall boards consist of one sheet of corrugated medium sandwiched between two sheets of liner. CrownPackages emphasizes the versatility of single-wall boards, noting their widespread use in shipping boxes and retail displays. Despite their simplicity, single-wall boards offer reliable protection and find utility across diverse applications, making them a staple in the packaging landscape.

Double-Wall Boards

Conversely, double-wall boards feature two sheets of corrugated medium nestled between three sheets of liner. CrownPackages underscores the structural integrity of double-wall boards, making them ideal for larger items or products requiring enhanced durability during transportation. With an additional layer of corrugated medium, double-wall boards provide superior strength and protection, ensuring the safe delivery of valuable goods.

Triple-Wall Boards

At the pinnacle of corrugated board design lies the triple-wall board, comprising three sheets of corrugated medium and four sheets of liner. CrownPackages highlights the exceptional robustness of triple-wall boards, which are commonly deployed for commercial components and the construction of produce bins. With multiple layers of corrugated medium and liner, triple-wall boards offer unmatched strength and durability, making them indispensable for heavy-duty packaging applications.

Conclusion

Corrugated cardboard’s impact on global transportation traces back to visionary innovators like Malcolm McLean, whose pioneering efforts revolutionized shipping operations with efficient loading and unloading processes. CrownPackages acknowledges the transformative power of corrugated cardboard in expediting shipping operations and fostering further advancements in packaging technology.

With a diverse array of corrugated stock types, CrownPackages offers tailored packaging solutions to meet unique requirements. From Normal Slotted Glued Containers (RSC) to specialized configurations like die-cut containers, each type is meticulously crafted to deliver optimal strength, durability, and protection for packaged goods.

Exploring flute types such as A, B, and E, CrownPackages highlights their unique characteristics and applications, offering insights into their cushioning properties and printing capabilities. Additionally, CrownPackages elucidates the distinct features of single-wall, double-wall, and triple-wall boards, aligning board selection with packaging needs to ensure optimal protection and transportation of products. CrownPackages continues to uphold the legacy of corrugated cardboard as a symbol of innovation, durability, and sustainability, offering bespoke packaging solutions tailored to the evolving needs of modern businesses.

Frequently Asked Questions

What is corrugated cardboard?

Corrugated cardboard is a robust packaging material crafted from thick paper stock or heavy paper-pulp. Its unique construction involves layers of paperboard with a fluted layer sandwiched between them, resulting in a sturdy box ideal for packaging.

How does corrugated cardboard differ from paperboard?

While both materials utilize paperboard for their outer and inner layers, corrugated cardboard distinguishes itself with a fluted layer sandwiched between these outer layers. This fluted layer provides enhanced strength and protection to the box, making it ideal for shipping and packaging applications.

What is the purpose of using corrugated boxes?

Corrugated boxes offer versatile packaging solutions suitable for packing a wide range of goods, including awkwardly shaped items. They provide protection during transit and are available in various sizes and shapes, ensuring flexibility and reliability in packaging.

What are two notable properties of corrugated cardboard?

Corrugated cardboard boasts properties that make it well-suited for packaging purposes. Its rigidity allows it to support heavy weight and pressure from stacked boxes during shipping. Additionally, its layers provide flexibility, making it ideal for wrapping individual items securely, such as books.

Why is corrugated cardboard considered advantageous?

Corrugated cardboard offers several advantages, including minimizing material usage while providing robust packaging solutions. Moreover, it is entirely reusable, designed to be easily collapsible and repurposed for multiple uses, reducing both packaging costs and environmental impact.