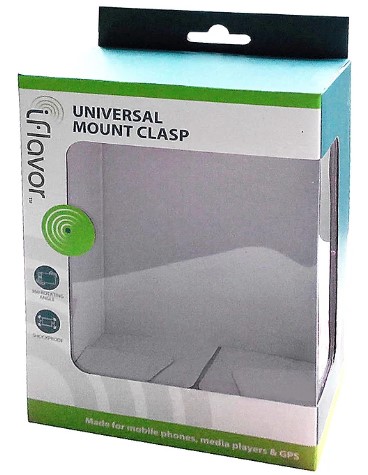

Think about the last time you visited a bakery. You likely noticed the boxes with openings on top, allowing a tantalizing glimpse of the treats inside even before the box was opened. This enticing preview is made possible by window patching, a technique widely used in custom packaging to enhance product visibility and appeal. CrownPackages recognizes the power of visual appeal, and window patching presents a unique opportunity to showcase your product’s brilliance.

What is Window Patching?

Window patching involves applying a thin plastic film to a die-cut window on packaging. This film allows customers to see the products inside before opening the package, making it particularly effective for products like baked goods, toys, and snacks. For CrownPackages, incorporating window patching can elevate the presentation of various products, showcasing their quality and allure.

Beyond aesthetics, window patching offers practical benefits:

Enhanced Product Visibility

CrownPackages understands that consumers are drawn to visually appealing products. Window patching allows your product to shine, showcasing its unique features and design elements. This can be particularly effective for products that rely heavily on visual appeal, like toys, baked goods, and cosmetics.

Elevated Brand Experience

Window patching adds a touch of sophistication and quality to your packaging. CrownPackages offers a variety of high-clarity films that ensure a pristine view of your product, creating a premium brand experience that resonates with customers.

Improved Consumer Confidence

By offering a sneak peek, window patching fosters trust and transparency. Customers can see exactly what they’re purchasing, reducing purchase anxiety and leading to a more satisfying buying experience.

Types of Window Patching Films

Two common types of films used in window patching are polyethylene terephthalate (PET) and polyvinyl chloride (PVC). PET film offers excellent protection and is suitable for consumer-facing products like food items. On the other hand, PVC film is more resistant to wear and tear but may not be ideal for packaging food due to potential degradation when exposed to UV rays.

The success of window patching hinges on selecting the ideal film for your product’s needs. CrownPackages offers a comprehensive selection of films to ensure a perfect match:

PET (Polyethylene Terephthalate)

This film is renowned for its exceptional clarity, strength, and resistance to tampering. CrownPackages recommends PET for most applications, particularly those involving food and consumer goods.

PVC (Polyvinyl Chloride)

PVC offers superior durability and moisture resistance, making it ideal for products exposed to harsh conditions. However, CrownPackages advises caution due to potential environmental concerns and a slight odor that may not be suitable for food packaging.

CrownPackages recognizes that one size doesn’t always fit all. We offer a variety of specialty films to cater to specific needs. For instance, polypropylene is ideal for bakery boxes, while laminated foil provides superior protection for light-sensitive products.

Other Window Patching Films

Beyond PET and PVC, there are several other types of window patching films available, each catering to specific product needs. From polyolefin for boxed goods to polyethylene for frozen foods, CrownPackages can choose the most suitable film for its diverse range of products.

Understanding Rigid vs. Flexible Windows

Cellophane window packaging offers CrownPackages an opportunity to showcase products with clarity and transparency. Flexible windows, made from polyester film, are affordable and eco-friendly, ideal for various package shapes. On the other hand, rigid windows, crafted from hard plastic resin, add a touch of luxury and durability, making them suitable for high-end products like cosmetics and pharmaceuticals.

The Window Patching Process

Window patching involves a specialized machine that applies a plastic film reel to packaging paper, creating the desired window. This efficient process ensures that the package is ready for use once the film is applied, streamlining production for CrownPackages.

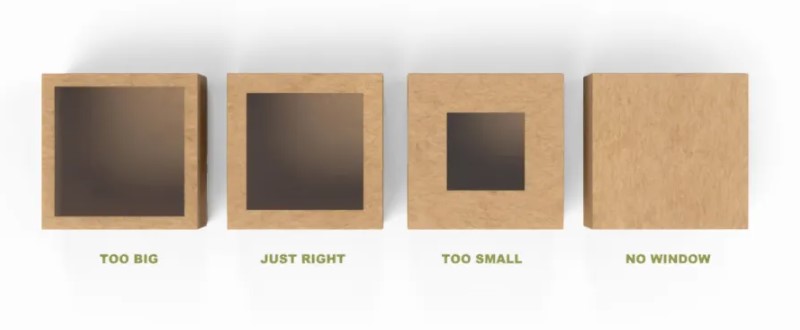

Considerations for Choosing the Right Window Patching

When selecting window patching for CrownPackages, factors such as window size, strength, and exposure to elements must be considered. Larger windows may require stronger films to prevent breakage, while high-end products demand sturdier packaging to maintain product integrity.

The CrownPackages Assistance for Seamless Window Patching Integration

At CrownPackages, we take window patching beyond a simple technique. We approach it as a strategic element within your overall packaging design. Our team of experts will guide you through every step of the process, from selecting the ideal film to ensuring flawless integration with your box design.

Our state-of-the-art window patching machinery utilizes cutting-edge technology to ensure precise application and rapid turnaround times. CrownPackages prioritizes efficiency and quality, delivering exceptional results that elevate your brand identity.

Conclusion

Contact CrownPackages today to explore window patching options tailored to your product needs. With skilled artists and comprehensive packaging solutions, CrownPackages can transform packaging visions into stunning reality. Request a free quote and discover how window patching can enhance your product presentation.