Cardboard stands as a versatile and widely used material in the packaging industry, celebrated for its strength, durability, and recyclability. CrownPackages sheds light on the diverse applications of cardboard, ranging from packaging boxes to display materials, showcasing its integral role in modern packaging solutions.

Composition and Characteristics of Cardboard

Comprising layers of paper pulp pressed together, cardboard offers a robust and resilient packaging solution suitable for various needs. CrownPackages highlights the distinctiveness of corrugated cardboard, featuring a wavy layer known as fluting that enhances its strength, particularly for shipping boxes. This unique composition balances functionality with eco-friendliness, contributing to its widespread adoption across the global packaging landscape.

The Manufacturing Process of Cardboard

Delving into the production process, CrownPackages provides insights into the meticulous steps involved in transforming raw materials into cardboard:

Raw Material Collection

The process begins with the collection of raw materials, including recycled paper and wood fibers, emphasizing sustainability and environmental responsibility.

Pulping

Raw materials undergo pulping, where they are broken down into fibrous pulp through mechanical or chemical methods, ensuring the purity of the material.

Cleaning for Pulp

Thorough cleaning eliminates impurities like bark, dirt, or ink residues, ensuring high-quality pulp for card board production.

Bleaching for a White Finish

Bleaching enhances the visual appeal of card board by achieving a consistent white color, meeting industry standards for aesthetic excellence.

Forming the Sheets

The pulped material is formed into large sheets, allowing for customization of thickness and characteristics based on intended usage.

Pressing

Sheets undergo pressing between large rollers to enhance density and strength.

Corrugation

The hallmark of corrugated card board, this process introduces flutes between sheets, imparting sturdiness and durability essential for secure shipping.

Cutting and Shaping

Finally, card board enters the cutting and shaping phase, where it is transformed into various products such as boxes and containers, showcasing its versatility in packaging solutions.

By unraveling the intricacies of cardboard production, CrownPackages underscores the significance of this ubiquitous material in delivering sustainable, reliable, and customizable packaging solutions tailored to diverse industry needs.

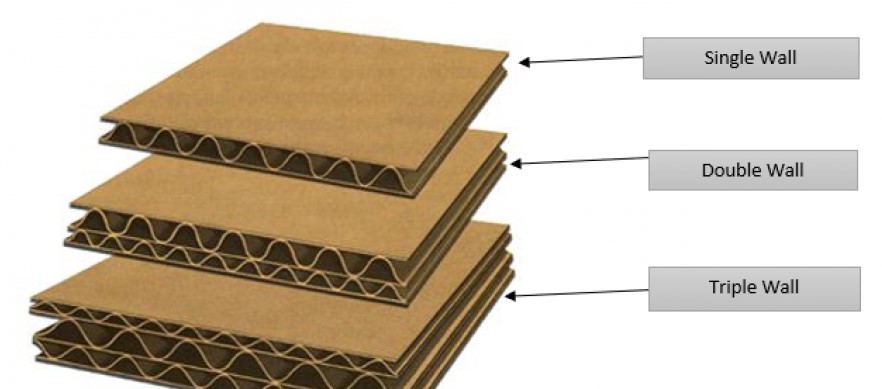

Types of Cardboard in Packaging

Cardboard comes in various forms, each tailored to meet specific packaging needs. CrownPackages elucidates the distinct characteristics and applications of single-wall, double-wall, and triple-wall card board, offering insights into their suitability for different packaging requirements.

Single Wall Cardboard

Single-wall card board features a single layer of corrugated material, providing basic strength and flexibility. CrownPackages highlights its cost-effectiveness and suitability for lightweight packaging applications, making it an economical choice for shipping and storage needs where additional protection is not required.

Double Wall Cardboard

With two layers of corrugated material, double-wall card board offers increased strength and durability compared to its single-wall counterpart. CrownPackages emphasizes its ideal application for heavier items and enhanced protection during transit. Widely used in shipping boxes, double-wall card board strikes a balance between strength and cost-efficiency, ensuring the safe transportation of goods.

Triple Wall Cardboard

Triple-wall card board stands as the strongest among the three types, boasting three layers of corrugated material. CrownPackages underscores its superiority in heavy-duty applications and transportation of large items, offering superior strength and resistance. Designed for industrial packaging, triple-wall card board provides robust protection for transporting bulky and sturdy goods.

Advantages of Choosing Cardboard for Packaging

Cardboard stands out as a preferred material for a multitude of applications, offering a blend of versatility, sustainability, and cost-effectiveness. CrownPackages explores the compelling reasons to opt for card board in packaging, emphasizing its lightweight yet robust qualities and its alignment with eco-friendly practices.

Versatility and Sustainability

Cardboard’s versatility makes it an ideal choice for packaging various products, from electronics to food items. CrownPackages highlights its sustainable nature, emphasizing its ability to reduce environmental impact through recycling. By opting for card board, businesses contribute to eco-friendly practices, aligning with global sustainability goals.

Cost-Effectiveness and Efficiency

The lightweight yet sturdy nature of card board contributes to cost-effective packaging solutions. CrownPackages underscores how card board reduces transportation costs due to its lightweight properties, enhancing overall efficiency in logistics and supply chain management. Businesses benefit from streamlined operations and reduced environmental footprint, optimizing both cost and resource utilization.

Customization and Aesthetic Appeal

Cardboard offers ample opportunities for customization to meet diverse product needs. CrownPackages explores how various finishing processes, such as printing and laminating, enhance the aesthetic appeal of card board packaging. By leveraging these options, businesses can create visually appealing packaging solutions that resonate with consumers, enhancing brand image and recognition.

Conclusion

Cardboard stands as a stalwart in the packaging domain, prized for its robustness, durability, and eco-friendly attributes. CrownPackages illuminates its layered composition, highlighting the pivotal role of corrugated card board with its reinforcing fluting. Through meticulous manufacturing, cardboard emerges as a sustainable and customizable solution, adept at meeting diverse packaging needs while maintaining environmental integrity.

From single-wall to triple-wall variants, card board offers a spectrum of options tailored to specific requirements. CrownPackages underscores card board’s versatility, cost-effectiveness, and aesthetic appeal, making it a preferred choice across industries. By leveraging its strength and customization potential, businesses can not only safeguard their products but also enhance brand image and consumer engagement, paving the way for a sustainable and impactful packaging future.