Custom rigid boxes offer a myriad of finishing options, allowing brands to create packaging solutions that not only protect their products but also convey luxury and sophistication. At Crown Packages, we understand the power of presentation. Custom rigid boxes are more than just containers, they’re an extension of your brand identity, captivating customers and creating a lasting impression. But beyond their sturdy structure, it’s the finishing touches that truly elevate rigid boxes into extraordinary luxury packaging. Here’s a comprehensive guide to the various types of finishes available for custom rigid boxes:

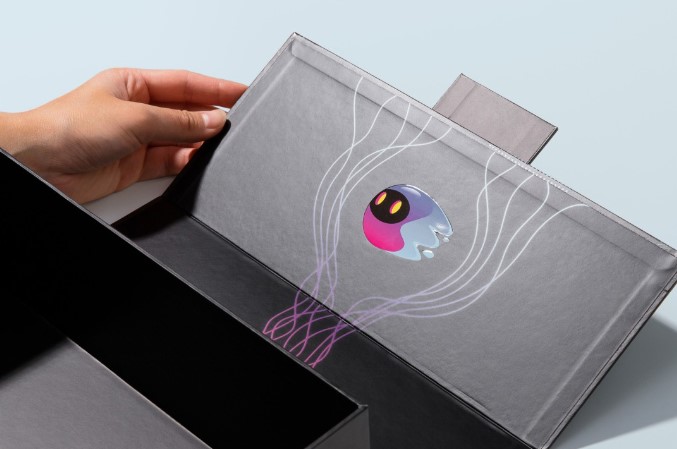

Partial vs. Full Finish

The way the decorative wrap interacts with the chipboard base of your rigid box establishes its visual foundation. Here’s a breakdown of the two main approaches:

Partial Finish

This style offers a more economical option. The decorative wrap covers the outer surfaces of the lid and tray, showcasing your brand design. The chipboard lips, where the wrap folds and adheres to the interior, remain visible.

Full Finish

For a touch of ultimate luxury, consider a full finish. Here, the entire chipboard base, including the inner wrap (often white or another complementary color), is enveloped by the decorative wrap. This creates a seamless, sophisticated aesthetic that emphasizes your brand identity.

Exterior Enhancements

Once you’ve chosen your base style, it’s time to explore the exciting world of exterior add-ons that bring your vision to life.

Coatings

A protective and decorative layer, coatings come in various options to suit your needs:

- Varnish: This clear ink creates a subtle, elegant finish, choose from satin, matte, or glossy to match your brand aesthetic. Varnish can be applied selectively (spot varnish) or across the entire surface (flood varnish).

- Aqueous Coating: Eco-friendly and practical, this water-based coating offers a glossy or matte finish. It’s fingerprint and scratch-resistant, making it ideal for high-traffic environments. Its food-safe properties make it perfect for packaging edibles and beverages.

- UV Coating: Delivering the highest level of gloss, UV coatings require ultraviolet light or sunlight to cure. While stunning, they prevent foil stamping and require complete hardening before embossing.

Lamination

A thin, protective plastic film applied to the wrap, lamination offers superior water and moisture resistance. It reduces creases and enhances durability, making it ideal for luxury packaging. Opt for matte lamination for a sophisticated feel, it provides the perfect base for foil stamping, embossing, and spot UV enhancements.

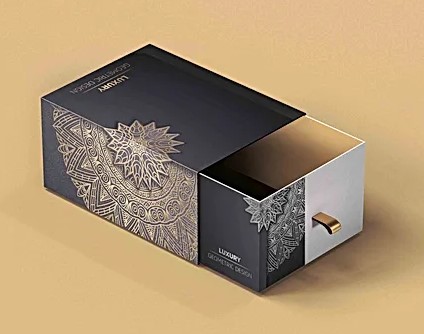

Hot Foil Stamping

Add a touch of brilliance with hot foil stamping. This technique uses heat and pressure to apply metallic or colored foils onto your design, highlighting your brand logo and creating a visually stunning effect.

Embossing & Debossing

For an extra tactile dimension, consider embossing (raised areas) or debossing (indented areas). These techniques add depth and texture to your design, making your boxes truly stand out. Embossing on foil-stamped material creates a particularly striking effect.

Flocking

Indulge in a luxurious touch with flocking. This process applies short fibers, like cotton, wool, or rayon, to specific areas or the entire wrap, creating a velvet or suede-like texture. Available in a variety of colors, flocking adds a unique sensory experience to your packaging.

Production Process of Custom Rigid Boxes

The journey of your custom rigid box begins with collaboration. Here’s a glimpse into the typical production process:

Conceptualization

Our design team works closely with you to understand your vision and product requirements. We’ll consider existing brand guidelines, product fit, artwork placement, and any retailer specifications. Once the concept and budget are finalized, we create a prototype for your approval.

Production

A blend of modern machinery and skilled craftsmanship brings your design to life. The printed wrap undergoes any necessary treatments like lamination. Meanwhile, the chipboard is precisely scored and cut to ensure perfect dimensions. Folding and assembly involve a combination of automated equipment and manual expertise, ensuring quality and consistency.

Delivery

We understand the importance of safeguarding your investment. During the design phase, careful consideration is given to packaging your rigid boxes for secure transport.

Testing of Custom Rigid Box Ensuring Impeccable Quality

At Crown Packages, we prioritize quality. Before your custom rigid boxes embark on their journey, they undergo rigorous testing:

Dimension Testing

In the custom rigid box packaging, precision is not just a preference, it’s a necessity. Each chipboard undergoes meticulous testing to guarantee exact dimensions. Why? Because precise measurements ensure the seamless adherence of the wrap, ensuring that your packaging looks impeccable and professional. Moreover, perfect dimensions mean your product fits snugly inside the box, enhancing its presentation and protection. Additionally, accurate sizing ensures that labels and stickers are positioned flawlessly, adding to the overall aesthetic appeal of your packaging.

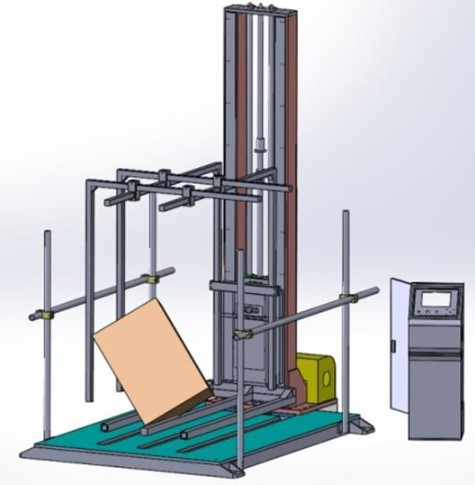

Drop Testing

At CrownPackages, we take reliability seriously. That’s why we subject our packaging to rigorous drop tests, adhering to established protocols from the International Safe Transit Association (ISTA). These tests simulate real-world scenarios, ensuring that your products remain protected even in the face of unexpected mishaps during transit. By conducting these tests, we guarantee that your packaging maintains its integrity and your products arrive at their destination unscathed, instilling confidence in both you and your customers.

Conclusion

In conclusion, at CrownPackages, we understand the importance of custom rigid boxes as representations of luxury, sophistication, and brand identity. Offering a wide range of finishing options including coatings, lamination, foil stamping, embossing, debossing, and flocking, we ensure that your packaging stands out and leaves a lasting impression.

Through collaboration and precision in our production process, we guarantee quality and consistency in every box we produce. Before shipment, rigorous testing ensures impeccable quality and reliability, safeguarding your investment and ensuring your products arrive safely. Choose CrownPackages for custom rigid boxes that elevate your brand and deliver exceptional customer experiences.

Frequently Asked Questions

What are custom rigid boxes?

How are rigid boxes made?

Sizing: Flat paperboard is cut and scored to the correct size.

Folding: The sides of the box are folded up and secured to form the base shape.

Printing: Custom designs and branding elements are printed onto the box.

Wrapping: The box is wrapped in decorative specialty paper, enhancing its visual appeal.

Why are rigid boxes expensive?

What are rigid boxes used for?

How thick is a rigid box?

What are the raw materials for rigid boxes?

Chipboard: Provides sturdiness and durability to the packaging.

Paperboard: Offers a smooth surface for printing and customization.

Corrugated Board: Provides additional strength and protection for heavier items.