Whether you are designing a brochure, packaging, or any printed material, knowing the difference between CMYK, RGB, understanding color models is crucial. But navigating the technical aspects of color reproduction can be a challenge. Here at CrownPackages, we’re committed to empowering you with knowledge. This comprehensive guide dives deep into CMYK for printing, the cornerstone of print production in packaging, ensuring you make informed decisions for your next packaging project.

What is CMYK for Printing and What Does It Stand For?

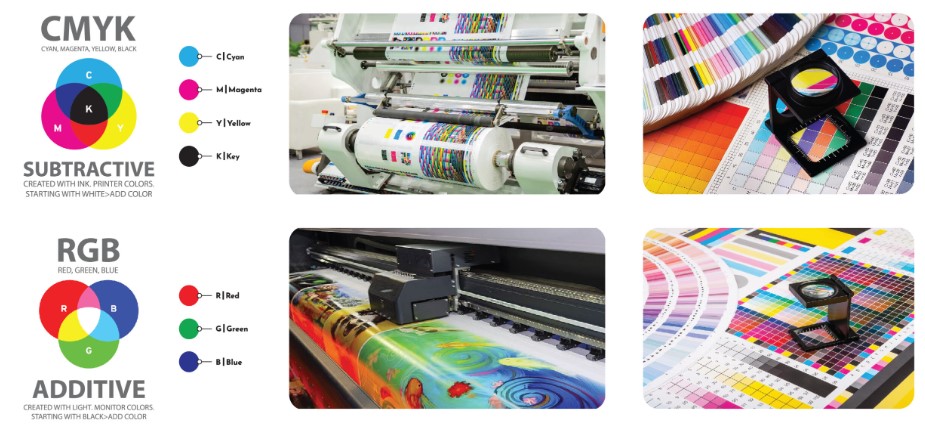

CMYK stands for Cyan, Magenta, Yellow, and Key (Black). This color model is essential for the four-color process printing standard in the industry. It’s the backbone of all print-related mediums, including brochures, documents, and packaging. Unlike RGB, which is used for digital screens, CMYK is specifically designed for printing. Each image in CMYK is separated into the four primary color pigments, allowing for a wide range of color combinations using minimal ink.

The Origin of ‘Key’ in CMYK for Printing

You might wonder why ‘K’ stands for black instead of ‘B’. Historically, Johann Gutenberg, the inventor of the printing press, referred to black as the ‘key’ color because it is the key plate in printing that aligns the other colors. Additionally, ‘B’ is already used to denote Blue in the RGB color system.

Why CMYK Reigns Supreme in Printing

- Cost-Effectiveness: CMYK inks are readily available and affordable, making it a budget-friendly choice for high-volume printing projects.

- Color Accuracy: The four-color process delivers a broad and vibrant color gamut, ideal for replicating a wide range of colors with impressive accuracy.

- Versatility: CMYK is compatible with various printing methods, including offset printing, flexographic printing, and digital printing, offering flexibility for your specific needs.

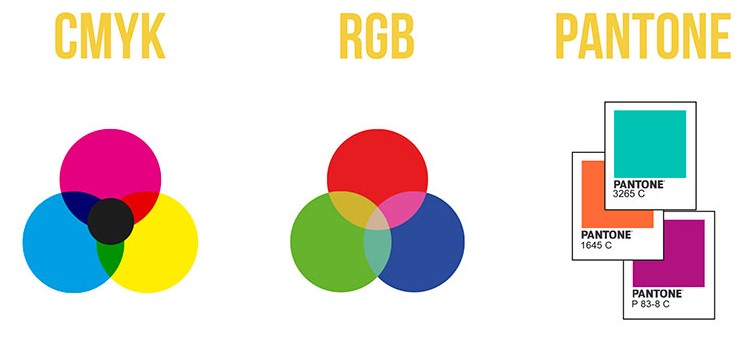

CMYK vs RGB vs Pantone

Understanding the differences between CMYK, RGB, and Pantone is vital for choosing the right color system for your project.

| Feature | CMYK | RGB | Pantone (PMS) |

| Method | Blends four colors | Arranges red, green, and blue pixels | Uses pre-mixed solid, single-color ink |

| Mediums | Printing | Digital screens (TVs, monitors, phones) | Printing |

| When to Use | Designs with multiple colors for print | Any digital design | Branding and exact color matching |

| Color Consistency | May vary between print jobs but cost-effective | Displays differently between screens | Identical colors from print to print, may vary across different mediums |

| Purpose | Efficient for printing | Designed for digital displays | Best for precise color matching |

| Advantages | Cost-effective, versatile, efficient | Ideal for digital, vibrant colors | Precise color matching, extensive color range |

| Disadvantages | Slight color variations in print jobs | Inefficient for printing on white backgrounds | Expensive, time-consuming |

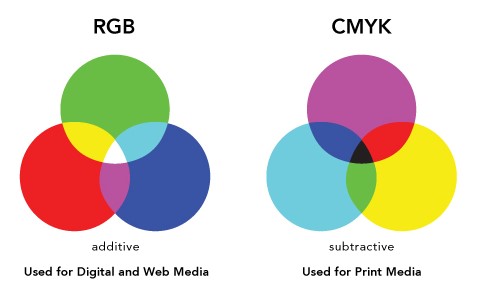

The Purpose of CMYK over RGB

CMYK is explicitly designed for printing, while RGB is for digital displays. In RGB, mixing the three colors (red, green, blue) to achieve white is inefficient, especially since most print media like paper is already white. CMYK reduces the ink needed by subtracting colors from a white background, making it more efficient for printing.

Why Converting from RGB to CMYK is Crucial

Since RGB and CMYK use fundamentally different approaches to color creation, an RGB file won’t translate perfectly to print. Certain colors achievable on a screen might not be reproducible with CMYK inks. To ensure color accuracy in your printed materials, it’s essential to convert your RGB files to CMYK before sending them to print.

Converting RGB to CMYK

To ensure accurate colors in print, convert your RGB projects to CMYK. Here’s how you can do it in Adobe Photoshop:

- Create a Replica: Make a copy of your original image and open both the copy and the original.

- Convert to CMYK: Select the copy and click Image > Mode > CMYK Color.

- Adjust Colors: Refer to the original RGB image and adjust the colors in the CMYK version as needed.

- Print Proof: Always view a printed proof to avoid costly errors and ensure color accuracy.

CMYK for Your Next Packaging Project with CrownPackages

For efficient and accurate printing, especially in packaging, CMYK is the preferred choice. It consumes less ink and provides consistent color output, making it ideal for offset printing, flexo printing, and digital printing. With CrownPackages, you can leverage the benefits of CMYK for your custom packaging projects, ensuring vibrant and accurate brand colors.

At CrownPackages, we understand the importance of color consistency in creating impactful packaging. That’s why we offer a comprehensive range of CMYK printing services:

- Expert Color Matching: Our team of color specialists works meticulously to achieve the perfect color match for your brand, ensuring your packaging reflects your vision flawlessly.

- State-of-the-Art Printing Technology: We utilize cutting-edge printing equipment that delivers exceptional color reproduction and detail, bringing your designs to life.

- Customizable Printing Solutions: Whether you require offset printing for high-volume production or digital printing for smaller runs, we offer tailored solutions to meet your specific needs and budget.

Tips to Optimize Your Packaging Design for CMYK Printing

Here are some valuable tips to keep in mind when designing for CMYK printing:

- Start with CMYK Color Profiles: Design your artwork using CMYK color profiles to ensure an accurate representation of how colors will appear in print.

- Be Mindful of Rich Blacks and Vibrant Colors: Deep blacks and highly saturated colors might not translate perfectly to CMYK. Consult with our design team to explore alternative options.

- Request a Printed Proof: Before finalizing your project, request a printed proof to confirm color accuracy and make any necessary adjustments.

Conclusion

Switching to CMYK for your printing needs, especially packaging, can significantly enhance the quality and consistency of your brand’s colors. CrownPackages offers expert solutions to help you achieve the best results with CMYK printing. Contact our specialists today to find the perfect color-matching system for your next packaging project and ensure your brand stands out.

Frequently Asked Questions

Is packaging design CMYK or RGB?

What is CMYK printing?

What is the suitable color for packaging?

1. Brighter Colors: Tend to reduce the seriousness of packaging.

2. Black: Adds sophistication.

3. Grey or Brown: Makes the packaging appear conservative or masculine.

4. Pink: Adds a feminine touch.

5. Red: Draws attention and can convey either energy or lower value, depending on the shade.

Can I convert RGB to CMYK?

Are stickers RGB or CMYK?

Why is red used in packaging?

1. Brighter Reds: Communicate lively and energetic brands or products but may denote lower value.

2. Darker Reds: Convey a more professional and premium offering. Red packaging is well-suited to youthful, energetic products.

What is the best color for packaging?

1. Blue: Universally liked, suitable for a wide audience.

2. Green and Blue: Ideal for kids, avoiding red.

3. Purple: Popular among teenagers and people in their 30s, adding a novel touch to packaging design.