The world of packaging can seem complex, filled with technical jargon and specialized processes. But fear not! One of the most important concepts, the dieline, is here to be explained. Dielines play a pivotal role in ensuring the seamless creation of physical packages. Let’s delve deeper into what dielines entail and how they’re essential for your Packaging operations.

What is a Dieline?

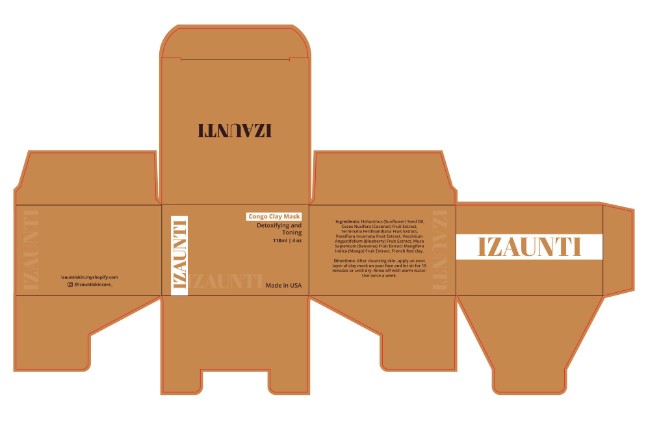

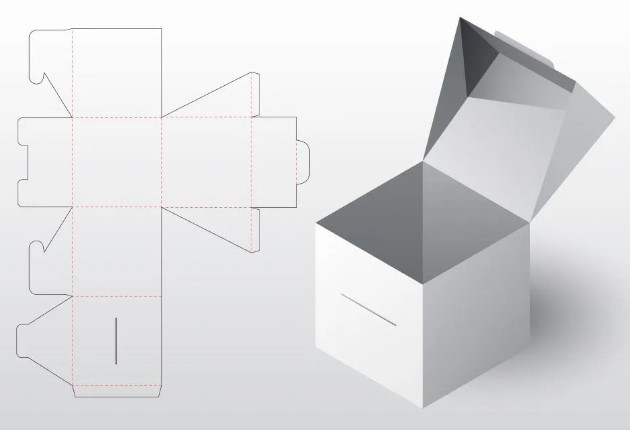

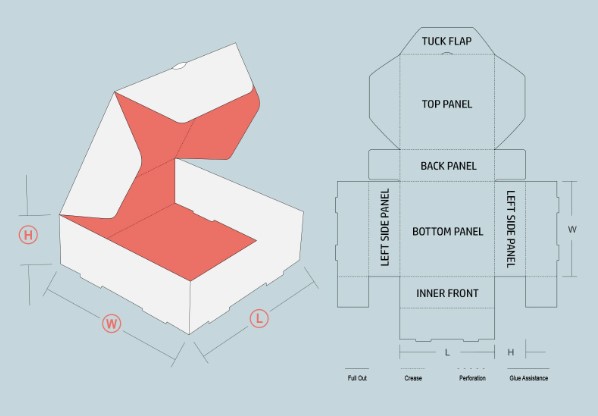

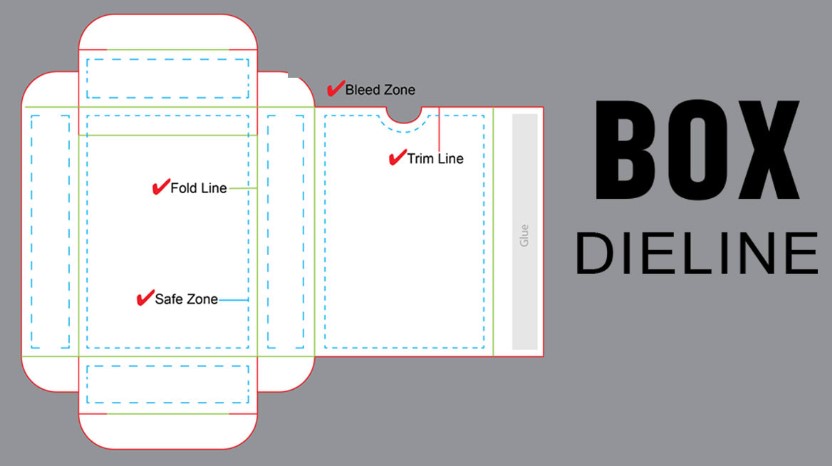

A dieline serves as a foundational blueprint that dictates the precise layout of a physical package before it transitions into production. Crafted meticulously by seasoned packaging designers, a dieline essentially acts as a flat diagram adorned with crucial markings indicating where the package’s fold and cut lines should be positioned.

Who Creates the Dieline?

Imagine a secret code that unlocks the perfect package. That’s essentially what a dieline is – a flat template that serves as a blueprint for your custom box. Typically, it’s the skilled hands of packaging designers that meticulously craft dielines. However, the task can also be undertaken by die cutters or printers, showcasing the collaborative nature of the packaging industry. From the simplest folders to the most intricate packaging designs, dielines are indispensable in ensuring accurate construction.

Why Dielines Matter

Dielines are beyond Just folds and cuts. Dielines play a crucial role in achieving packaging excellence. Here’s how they benefit you:

- Flawless Functionality: Dielines guarantee your packaging assembles correctly, with clean folds and precise cuts. This translates to a professional-looking product that protects its contents effectively.

- Design Harmony: Dielines allow you to visualize how your artwork interacts with the packaging structure. You can see where logos, graphics, and text will be placed, ensuring a cohesive and visually appealing final product.

- Manufacturing Efficiency: Clear dieline specifications minimize errors during production. CrownPackages’ team can readily interpret the dieline, leading to a smooth and efficient printing process, saving you time and money.

- Reduced Waste: Accurate dielines minimize the risk of mistakes, preventing wasted materials and ensuring a more sustainable packaging process – a priority for both CrownPackages and many of our customers.

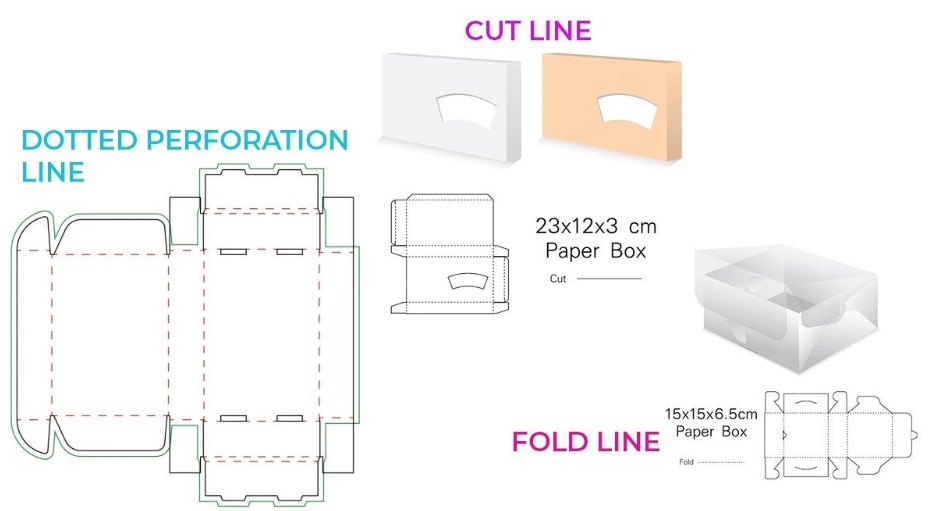

Types of Lines in the Dieline

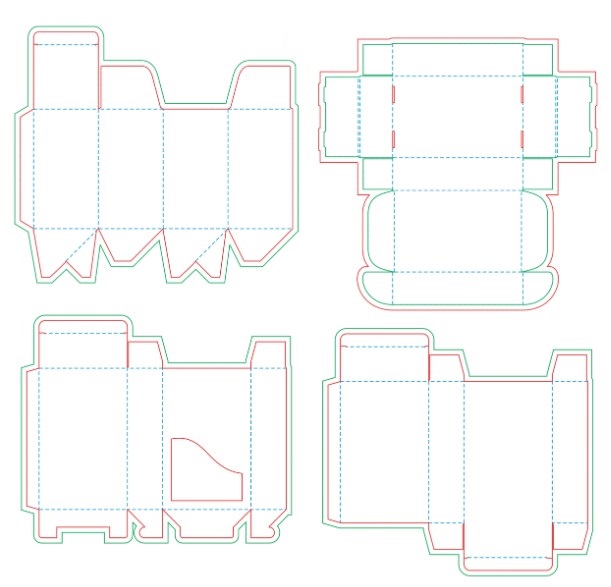

Dielines encompass three primary types of lines, each serving a distinct purpose:

- Dotted Perforation Lines: These dotted lines guide the process of perforating the packaging, enabling easy tearing or opening.

Cut Lines: Cut lines delineate precisely where the package should be cut, ensuring clean and accurate edges.

Fold Lines: Fold lines dictate where the package should be folded, facilitating the seamless assembly of the final product.

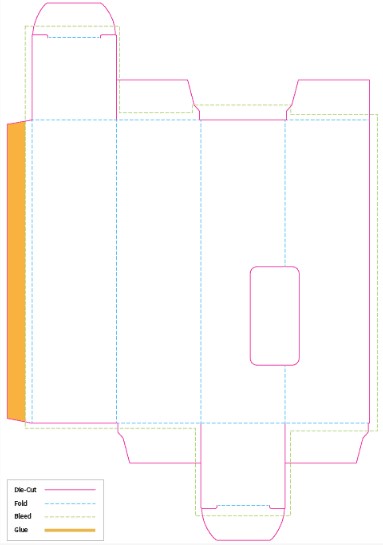

By segregating these lines into distinct layers and colors, printers can effectively navigate the die cutting process, ensuring precision and accuracy.

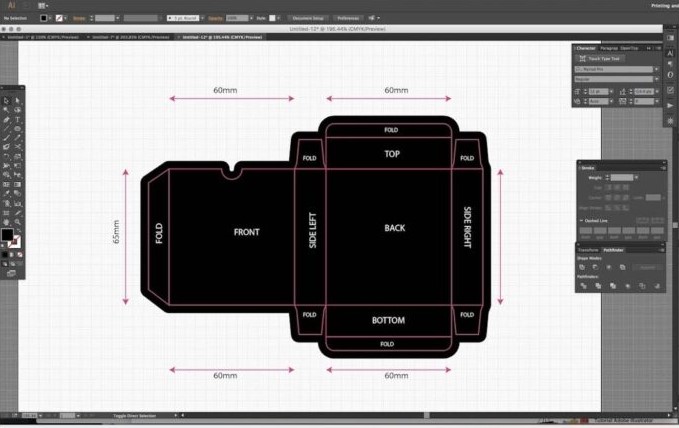

How to Make a Dieline

Crafting a dieline requires meticulous attention to detail and precision. To create your own dielines, start by dissecting a similar package, meticulously measuring its dimensions, and translating these measurements into a flat template. Utilize graphic design software like Adobe Illustrator to bring your dieline to life, ensuring that each line is meticulously positioned for optimal accuracy.

Whether you’re a seasoned designer or just starting your packaging journey, CrownPackages has options to suit your needs:

- Free Dieline Request: For a quick and easy solution, utilize our free dieline request form. Simply provide the desired box dimensions and specifications, and our experts will create a custom dieline for you, free of charge.

- DIY Dieline Creation: For those comfortable with design software like Adobe Illustrator, creating your own dieline is an option. However, remember, precise measurements and adherence to industry standards are crucial.

- Expert Design Collaboration: At CrownPackages, we offer a team of experienced designers who can collaborate with you to bring your packaging vision to life. From concept development to dieline creation, we’ll guide you through every step.

Using Adobe Illustrator for Creating Dielines

Adobe Illustrator stands as a stalwart tool in the realm of dieline creation. By following specific steps to set up your dielines correctly within Illustrator, you can ensure that your dielines are not just accurate but also scalable and adaptable to various printing processes.

You Can’t Use Adobe Photoshop to Create Dielines: While Adobe Photoshop boasts immense capabilities in the realm of graphic design, it falls short when it comes to creating dielines. Unlike Illustrator, Photoshop lacks the ability to generate vector-based artwork, essential for ensuring precise printing and scalability without compromising on quality.

What Else Do Dielines Show?

Beyond guiding cutting and folding, dielines also serve as a visual roadmap for packaging design. They indicate the precise placement of logos, graphics, and text, ensuring that each element is strategically positioned for maximum visual impact. Moreover, dielines help identify potential manufacturing errors, allowing for preemptive adjustments to be made before production commences.

Need a Hand Making Your Dieline?

If you find yourself in need of assistance with dieline creation, CrownPackages is here to help. Our dieline request service offers custom-made dielines free of charge, empowering you to bring your packaging ideas to fruition with confidence and ease. With our unwavering commitment to excellence and cutting-edge technology, CrownPackages stands ready to support your packaging needs every step of the way.

Conclusion

With a comprehensive understanding of dielines, CrownPackages is well-equipped to navigate the intricate landscape of packaging design and production. By leveraging precise dielines and harnessing the expertise of a multidisciplinary team, CrownPackages can ensure that each package is crafted with precision and care, delivering exceptional results every time.

Frequently Asked Questions

What is a die line or die cut?

What is the difference between dieline and mockup?

How do you read a die line?

YELLOW: DESIGN AREA: Where the design will be visible.

ORANGE: LID LIP/EDGE: Visible on the lid or base, but not suitable for intricate design.