Cardboard and corrugated cardboard, while commonly used terms, refer to distinct materials in the domain of packaging. The general perception might be that they are interchangeable, but a closer look reveals the specific roles each plays in various applications.

Custom made corrugated boxes, often underappreciated, hold significant importance in both our personal and professional lives. Found in homes, offices, garages, retail establishments, restaurants, and more, these boxes are ubiquitous. They fulfill essential roles, particularly in shipping and storage.

The versatility of corrugated boxes extends further. They often play a dual role in retail packaging, serving as both a protective container during transit and a display option on store shelves. This dual functionality showcases the practicality and efficiency of corrugated cardboard in the entire product lifecycle. Moreover, corrugated boxes demonstrate sustainability. Many of these boxes are designed to be recyclable, contributing to eco-friendly practices in packaging. This aligns with the growing awareness and preference for environmentally conscious choices.

Distinguishing Corrugated from Cardboard

Understanding the contrast is crucial. Corrugated boxes, crafted from corrugated cardboard, dominate shipping due to their protective and robust nature, with approx. 95% usage in North America. Corrugated cardboard comprises three layers: liner boards on the outside and a wavy flute layer. In contrast, cardboard, a thicker paper stock, finds application in smaller packaging but lacks the protective attributes of corrugated material. Corrugated stands out with its three-fiberboard layers, ensuring enhanced durability, protection, and adaptability, making it an optimal choice for various shipping needs.

Comparison Between Cardboard and Corrugated Boxes

| Feature | Corrugated Boxes | Cardboard Boxes |

| Composition | Three-layered with a curly center layer | Best for lighter weight; thick layers pasted without spaces |

| Common Usage | Mailer boxes, shipment purposes | Packaging boxes like bakery, candle boxes, etc. |

| Sturdiness | High | Not as hard, requires additional protection |

| Suitable For | Heavyweight objects, e.g., shoe boxes | Lighter weight objects |

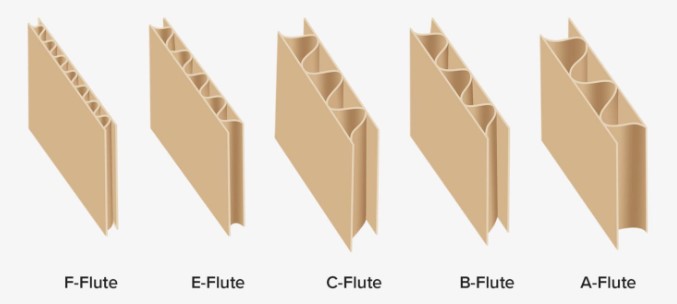

Distinct Flute Grades for Your Custom Made Corrugated Boxes

The flute, nestled between the liners, distinguishes corrugated boxes from their cardboard counterparts. The flute size dictates box wall thickness and contributes to stacking strength. Flutes, labeled with letters, denote size, measured by thickness and flutes per linear foot. Common flute sizes include:

- A-Flute (1/4” thick, 33 flutes per linear foot): Ideal for fragile items with substantial protective thickness.

- B-Flute (1/8” thick, 47 flutes per linear foot): Deceptively strong, suitable for counter displays or canned goods, and popular for die-cut designs.

- C-Flute (3/16” thick, 39 flutes per linear foot): Widely recognized, commonly used in shipping boxes.

- E-Flute (1/16” thick, 90 flutes per linear foot): Thin but efficient, used for folding carton boxes as an alternative to paperboard, offering easy storage and printability.

- F-Flute (1/32” thick, 125 flutes per linear foot): Among the thinnest, with a smooth surface for sharp printed graphics.

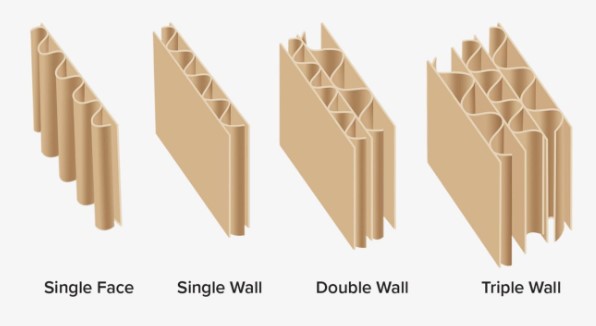

Corrugated Board Thickness and Structure

Having delved into paper liners and flute grades, let’s explore thickness variations. Here’s an overview of standard thickness options:

- Liner Board: The surface layer of the fiberboard sheet where the flute is adhered.

- Single Face: Consists of one liner board with the visible side displaying glued flute.

- Single Wall: The most prevalent thickness, featuring two liner boards with fluted fiberboard in between.

- Double Wall: Comprising three liner boards and two fluted fiberboards sandwiched between them.

- Triple Wall: Incorporating four liner boards and three fluted fiberboards, offering robustness for heavier weights.

For double and triple walls, different combinations of flute grades are possible, including:

- AC Flute: A combination of the two most protective grades, ideal for enhanced protection during harsh shipping and handling.

- BC Flute: A versatile choice, providing high-level transit protection and commonly used for shipping boxes.

- EB Flute: Ensures superior transit strength and safety, with the outer E-Flute allowing for excellent, high-quality printing.

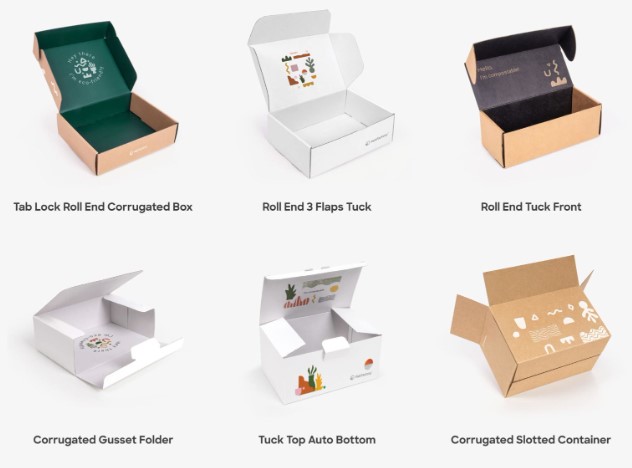

Box Styles

Now, considering construction and thickness, let’s delve into box styles, the final aspect before exploring quality control. Custom corrugated boxes, tailored by combining layers, selecting flute grades, or incorporating interior padding, can meet diverse packaging needs.

Choosing the right corrugated packaging box involves not only considering the material but also finding the perfect fit for your products. Corrugated boxes are available in diverse shapes and sizes to ensure items are neither cramped nor excessively spacious.

Some common styles for corrugated packages include:

- Regular Slotted Container (RSC): The most prevalent option, resembling classic shipping boxes. All flaps are of equal length, and the outer length flaps meet in the middle when closed, requiring tape for secure sealing.

- Full Overlap Container (FOL): This type provides added strength as both sets of outer flaps fully overlap, creating a double-layered top and bottom.

- One Piece Folder (OPF): Commonly used for books and media materials, these boxes are creased, slotted, and folded into shape.

- Full Telescope Design (FTD): Featuring separate top and bottom parts that fit over each other, the double walls offer enhanced strength.

To seal these boxes, options include packaging tape, tuck-in flaps, or strapping for heavy-duty loads. While the array of choices may seem overwhelming, tools and services are available for assistance. Standard box templates can be easily found online for simpler needs. For more intricate requirements, sophisticated software like ArtiosCAD, Impact, or Packmage allows designing full 3D models and custom die-cut templates. If uncertainty persists, a free consultation with our packaging team can provide guidance tailored to your unique needs, covering dielines, box styles, varnish, and more.

Benefits of Custom Made Corrugated Boxes

Corrugated boxes stand out as a popular choice among various packaging materials, offering distinct advantages for shipping and packaging.

Protection for Transportation and Shipping Safety

Their unparalleled protective qualities make them a reliable option, ensuring the safe transportation of goods. Notably, these boxes provide robust defense even for fragile items like glass and chemical liquids, thanks to the tear-resistant nature of corrugated cardboard. The durability of corrugated boxes has made them a staple in shipping and fulfillment strategies for many companies.

Cost-Effective Solution

From a cost perspective, corrugated boxes prove to be a cost-effective solution for businesses. Their relatively low manufacturing costs, especially in comparison to custom boxes, contribute to cost savings. The lightweight nature of these boxes and their easy storage further add to the overall economic benefits by reducing storage and transportation expenses.

Customization Options and Versatility

The customization options for corrugated boxes are extensive, offering versatility in terms of boards, weights, adhesives, coatings, and various treatments. The range of possibilities includes flame resistance and static control. Additionally, corrugated boxes can be folded into diverse shapes and sizes, providing adaptability for different packaging needs. The extensive graphic design options further allow businesses to create unique and branded packaging solutions.

Environment-Friendly Material

Corrugated packaging aligns with environmental considerations, making it an eco-friendly choice. Consumer preferences, as indicated by an Accenture survey, highlight the importance of products designed for reuse or recycling. Corrugated boxes receive positive recognition, with 55% of respondents considering paper products the best option for the environment. The environmental benefits of corrugated boxes include easy recyclability, high recycling rates, renewable materials, and a commitment to sustainable forestry practices.

Recyclability, Sustainability and Reusability

The recyclability of corrugated boxes is a notable advantage, with a significant portion being recycled annually, contributing to a 96.5% recycling rate in 2018. The renewable nature of corrugated packaging, often made from recycled materials ranging from 70-100%, further supports sustainable practices. Manufacturers source paper from sustainable forests, demonstrating a commitment to responsible environmental management.

Corrugated shipping boxes exhibit reusability through their collapsible design, enabling convenient storage for future use. Additionally, these boxes contribute to energy savings as their production primarily involves recycled materials, reducing overall energy consumption. The absence of dyes and bleaches in their production makes them an environmentally conscious choice. Moreover, their relatively light weight results in transportation cost savings.

Efficient and Space-Saving

In terms of efficiency, corrugated boxes offer robust protection without the need for excessive padding, and their stackable and collapsible design minimizes storage space requirements. This multifaceted efficiency makes corrugated boxes a practical and sustainable choice for various packaging needs.

Conclusion

In summary, custom made corrugated boxes are indispensable in diverse settings, offering dual functionality in retail packaging and contributing to sustainability trends with their recyclability and use of renewable materials. The benefits of corrugated boxes include their protective nature, cost-effectiveness, and versatility, making them an environmentally conscious choice. Their recyclability, sustainability, reusability, and efficient use of space make corrugated boxes a holistic solution for various packaging needs.

Frequently Asked Questions

What are custom corrugated boxes?

Can cardboard boxes be customized?

Why is corrugated expensive comparitively to cardboard?

What are the benefits of custom boxes?

2. Protects your product during shipping.

3. Promotes customer satisfaction.

4. Turns customers into brand ambassadors.